Menu

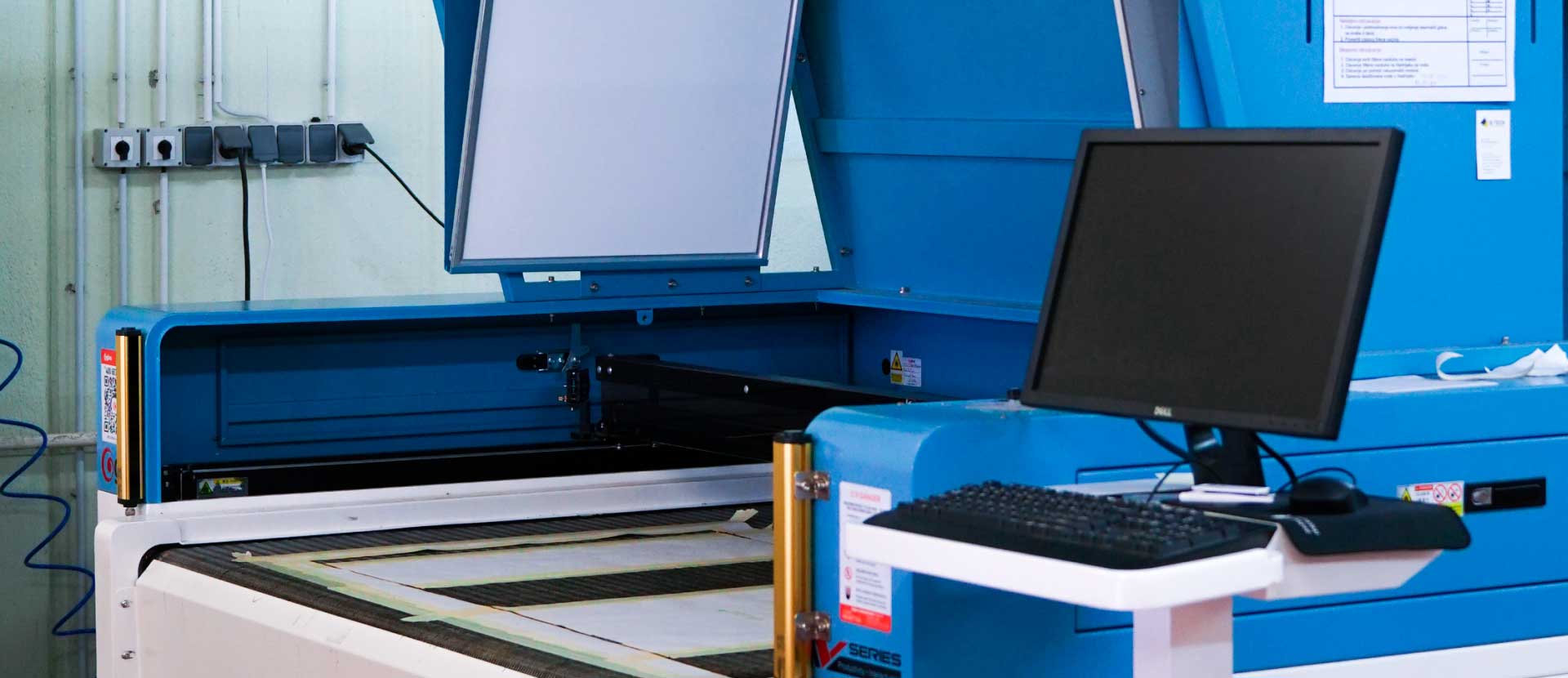

Laser cutting of textiles is a non-contact process in which there is no contact between the fabric and the cutting body. The laser beam melts the material, eliminating material twisting as well as damaged and sealed edges. We obtain clean, perfectly sealed edges.

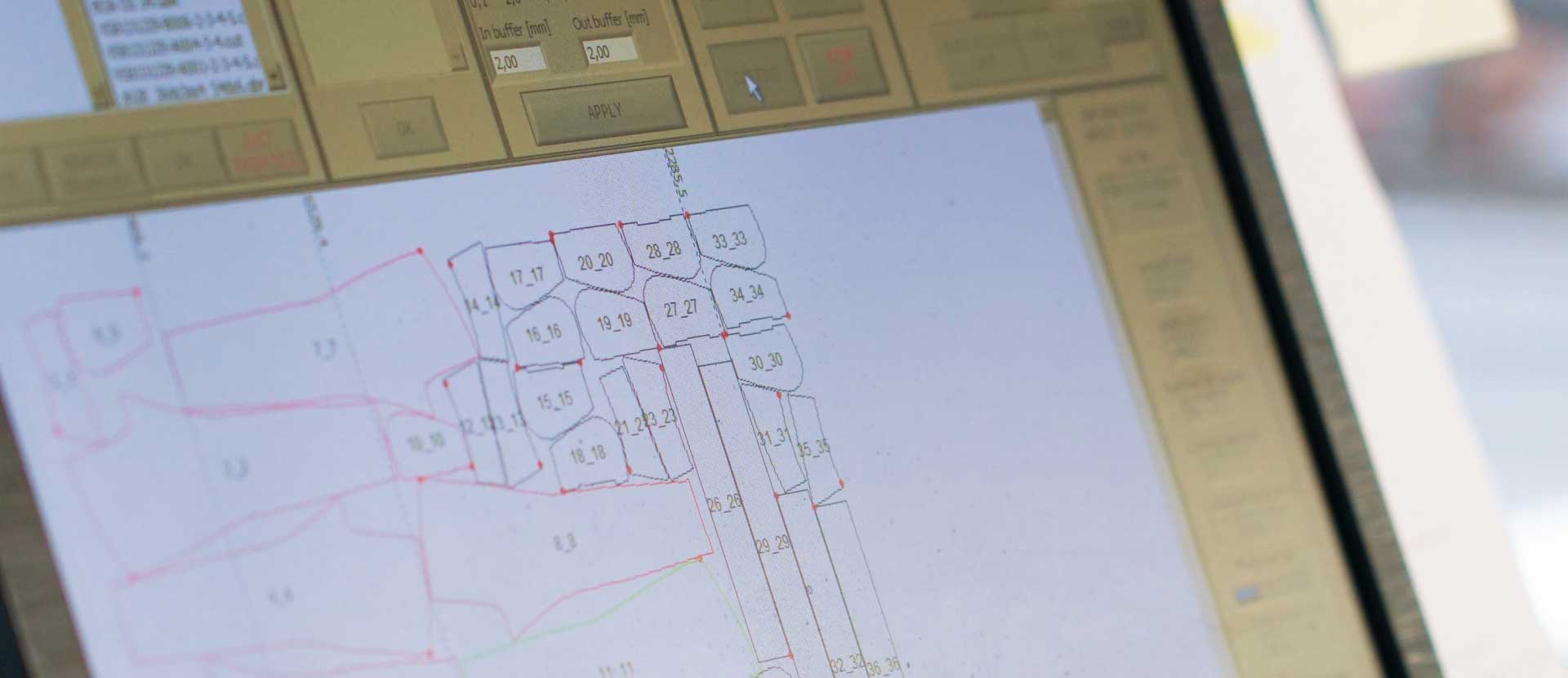

The laser is equipped with special visual software that enables fast textile cutting, produced by the digital printing technology (digital printing). Laser can, with an aid of a camera, recognize contouring and graphics, resulting in precisely cut edges with minimal material waste. It is especially suitable for cutting digitally printing clothing pieces such as sports jerseys, cycling clothing, swimsuits, and more. Laser technology allows cutting of any type of fabric.

Textiles suitable for laser cutting:

Double laser heads enable improved production efficiency

Precise contour cutting

Productivity

Contactless processing (no contact between fabric and cutting mechanism)

Minimal material waste

No fabric crushing or pulling

Clean and perfectly sealed edges during laser cutting

Automatic detection of contours printed with sublimation (digital printing)

Graphic preparation

Laser cutting

Final finishing processes

Milana Prpića 49

49243 Oroslavje, Croatia